The LT1 engine, found in vehicles like the fourth-generation Chevrolet Camaro and Corvette, is known for its powerful performance. However, one critical aspect that every LT1 owner needs to focus on is the 192-97 LT1 cooling system. Keeping the engine at optimal temperature is essential for avoiding overheating and other performance-related issues. In this article, we'll explore the unique cooling design of the LT1, common problems associated with the 192-97 LT1 cooling system, and how to maintain and upgrade it for better efficiency.

Overview of the 192-97 LT1 Engine and Its Cooling System

The LT1 engine was first introduced in 1992 as part of GM's Gen II small-block V8 engines. The engine was designed to offer more power and fuel efficiency than its predecessors, making it a popular choice for performance enthusiasts. The engine produced significant power for its time, but it also required a highly effective cooling system to keep it running efficiently.

Unlike many engines, the 192-97 LT1 cooling system is a "reverse-flow" design. This innovative feature allows coolant to circulate through the cylinder heads before moving through the engine block. This method prioritizes cooling the hottest parts of the engine, ensuring that combustion chambers and heads are cooled more effectively than with traditional "conventional-flow" systems, where coolant passes through the block first.

The reverse-flow cooling system was intended to reduce engine knock, improve fuel efficiency, and allow for higher compression ratios, all while managing the engine's temperature under intense performance conditions.

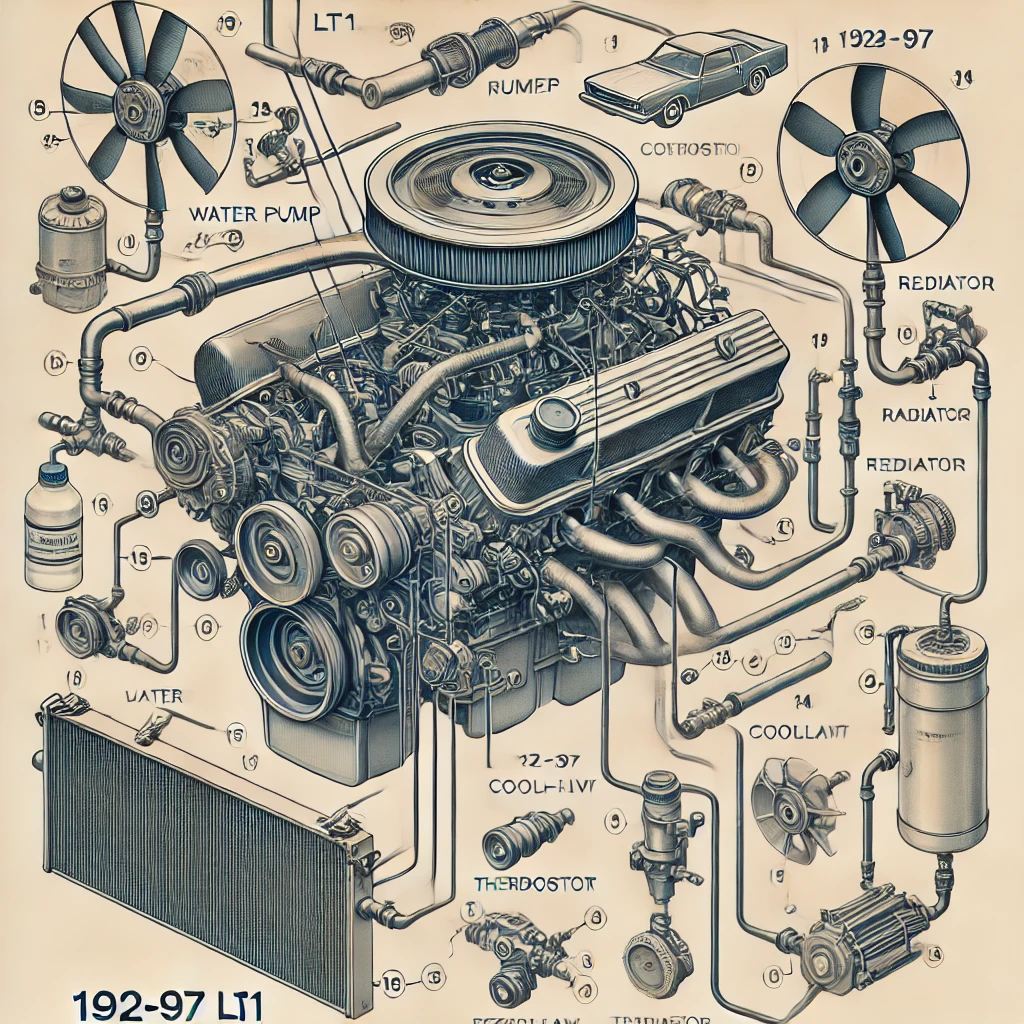

Key Components of the 192-97 LT1 Cooling System

Understanding the components of the LT1 cooling system will help you diagnose and maintain it properly. Below are the main parts involved:

- Water Pump: The water pump is critical for circulating coolant throughout the engine. In the LT1, it's driven by the camshaft, which makes it unique compared to traditional belt-driven water pumps.

- Radiator: The radiator is the main heat exchanger where hot coolant from the engine is cooled by air before being recirculated.

- Thermostat: The thermostat regulates the coolant flow and maintains the engine’s temperature. When the engine is cold, the thermostat stays closed, allowing it to warm up. Once the engine reaches its operating temperature, it opens to allow coolant flow.

- Coolant: LT1 engines use a specific type of coolant, typically Dex-Cool, which is designed to be compatible with the aluminum heads and other components in the engine.

- Coolant Temperature Sensors: These sensors help monitor the engine’s temperature and provide feedback to the electronic control unit (ECU), which in turn adjusts the cooling system.

Common Issues with the 192-97 LT1 Cooling System

Despite the innovative design of the reverse-flow system, the 192-97 LT1 cooling system is not without its problems. Here are some common issues that LT1 owners might encounter:

1. Water Pump Failure

The water pump in LT1 engines is camshaft-driven, which makes it prone to wear and tear over time. When the water pump starts to fail, it can lead to insufficient coolant circulation, causing overheating. Symptoms of a failing water pump include coolant leaks, high engine temperatures, and a noisy pump.

2. Clogged or Leaking Radiator

Over time, radiators can get clogged with dirt, debris, and corrosion, reducing their efficiency in cooling the engine. A leaking radiator can also cause low coolant levels, leading to overheating. Keeping the radiator clean and free of obstructions is crucial for the LT1’s cooling system to function properly.

3. Thermostat Stuck Open or Closed

A malfunctioning thermostat can cause significant cooling problems. If the thermostat gets stuck open, the engine will take longer to warm up, affecting fuel efficiency and performance. On the other hand, if it’s stuck closed, coolant won’t circulate properly, leading to overheating. Replacing the thermostat every few years as part of your maintenance routine can prevent this issue.

4. Coolant Leaks

Leaks are one of the most common issues in the LT1 cooling system. The water pump, radiator hoses, or gaskets can all develop leaks over time. A coolant leak not only causes low coolant levels but can also lead to more significant damage if the engine overheats.

5. Air Pockets in the Cooling System

Air pockets can form in the LT1 cooling system during a coolant change or if there’s a leak. These air pockets can block the flow of coolant, causing hotspots in the engine and potentially leading to overheating. Properly bleeding the cooling system after maintenance can help eliminate air pockets.

How to Maintain the 192-97 LT1 Cooling System

Maintaining the 192-97 LT1 cooling system is essential to avoid overheating and engine damage. Here are some key maintenance steps to follow:

1. Regular Coolant Changes

Over time, coolant can become contaminated or lose its effectiveness. It’s essential to flush and refill the cooling system with fresh coolant every 2 to 3 years. Using the recommended Dex-Cool coolant will ensure compatibility with your LT1 engine.

2. Inspect the Water Pump and Belts

Given the importance of the water pump, regularly inspecting it for leaks or unusual noises is vital. The camshaft-driven pump is more prone to failure than traditional designs, so replacing it when you notice signs of wear is a smart preventative measure.

3. Check for Leaks

Regularly check the radiator, hoses, and seals for any signs of leaks. Early detection of leaks can save you from expensive repairs and engine damage caused by overheating.

4. Bleed the Cooling System

Whenever you change the coolant or suspect an air pocket, be sure to bleed the system properly. This ensures that no air pockets remain in the cooling system, which can cause overheating.

Upgrades to Improve the LT1 Cooling System

If you’re looking to improve the performance and reliability of the LT1 cooling system, consider the following upgrades:

1. High-Flow Water Pump

Upgrading to a high-flow water pump can improve coolant circulation, particularly in performance applications where the engine generates more heat. A high-flow pump reduces the likelihood of overheating under heavy load conditions.

2. Aluminum Radiator

A more efficient aluminum radiator with larger cooling fins can improve heat dissipation, keeping your LT1 engine cooler, especially during intense driving or in hotter climates.

3. Electric Fans

Replacing the stock mechanical fan with electric fans can offer more consistent cooling, particularly at low speeds or when idling. Electric fans provide better control over engine temperatures and free up engine power that’s otherwise used to drive mechanical fans.

4. Upgraded Thermostat

An upgraded thermostat that opens at a lower temperature can improve cooling performance by allowing coolant to flow earlier and keep the engine from overheating during aggressive driving.

Conclusion

The 192-97 LT1 cooling system is a critical component for maintaining the performance and longevity of your LT1 engine. While the reverse-flow design provides enhanced cooling for high-compression engines, it’s not immune to problems like water pump failures, coolant leaks, or air pockets. By staying on top of regular maintenance and making targeted upgrades, you can keep your LT1 engine cool, efficient, and performing at its best for years to come.

Categories: Technology